Maximizing regeneration efficiency with reliable technology.

Polishing slurries primarily use abrasives and DI Water for wafer planarization, and they also include additives like dispersants for particle stabilization, oxidizers, pH adjusters, and corrosion inhibitors, depending on the characteristics of the semiconductor film being polished.

Environmental protection is our starting point, and social value is our direction.

We are growing into a company that realizes the ESG vision by creating a sustainable industrial ecosystem through resource recycling.

Reusing chemical raw materials — abrasives and ultrapure wate r— can significantly reduce the amount of slurry and wastewater used in the production process.

The effect of reducing exhaust fumes from the transport of raw material slurry and wastewater treatment chemicals, as well as the chemical agents used in wastewater treatment.

Expectation of quality assurance and maintenance of process quality through the reuse of recovered raw materials.

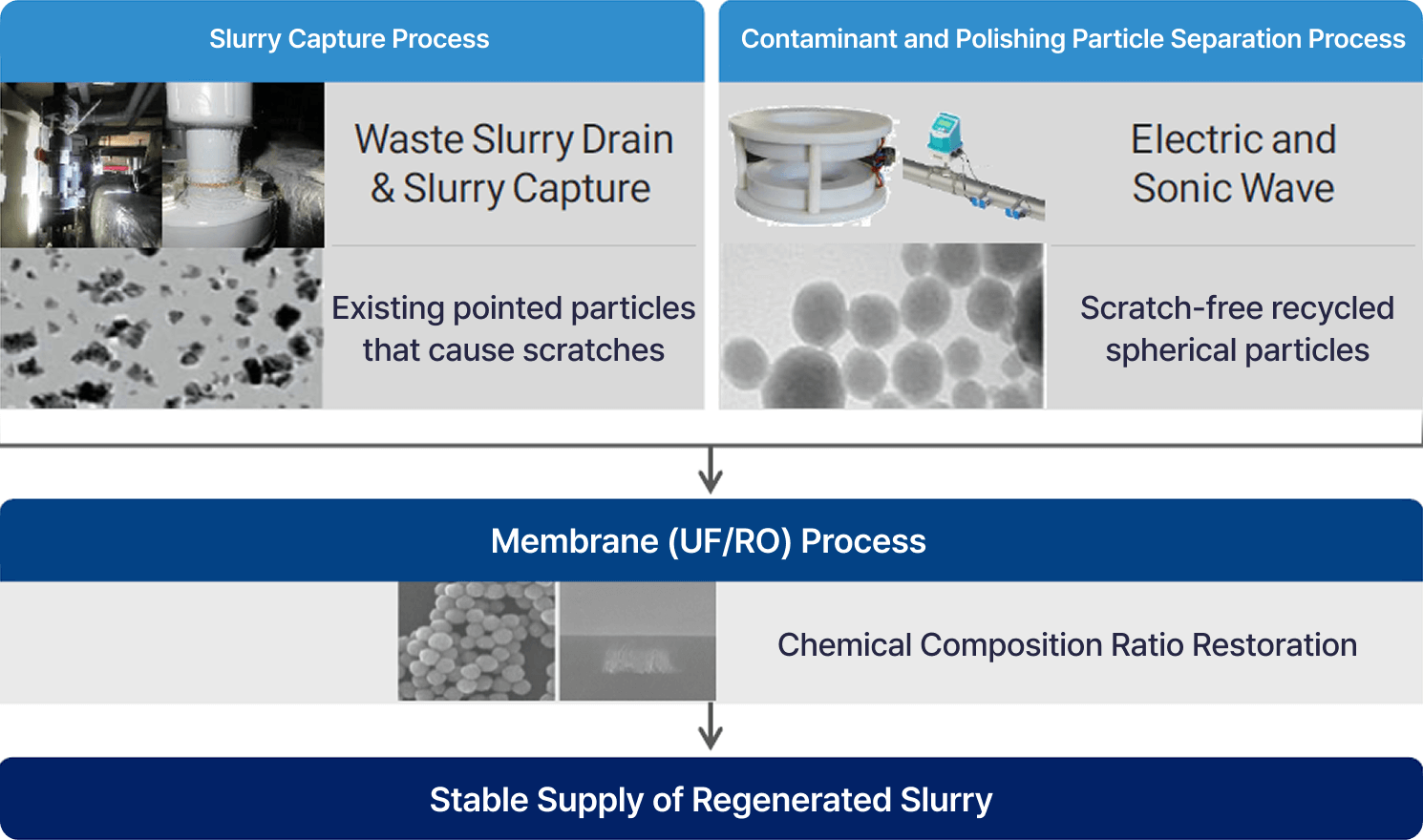

Slurry recycling is expected to reduce the occurrence of micro-scratches and increase production yield.

The recycled slurry can be used without sedimentation because it is supplied directly to the production process without designated storage space or logistical transfer distance.

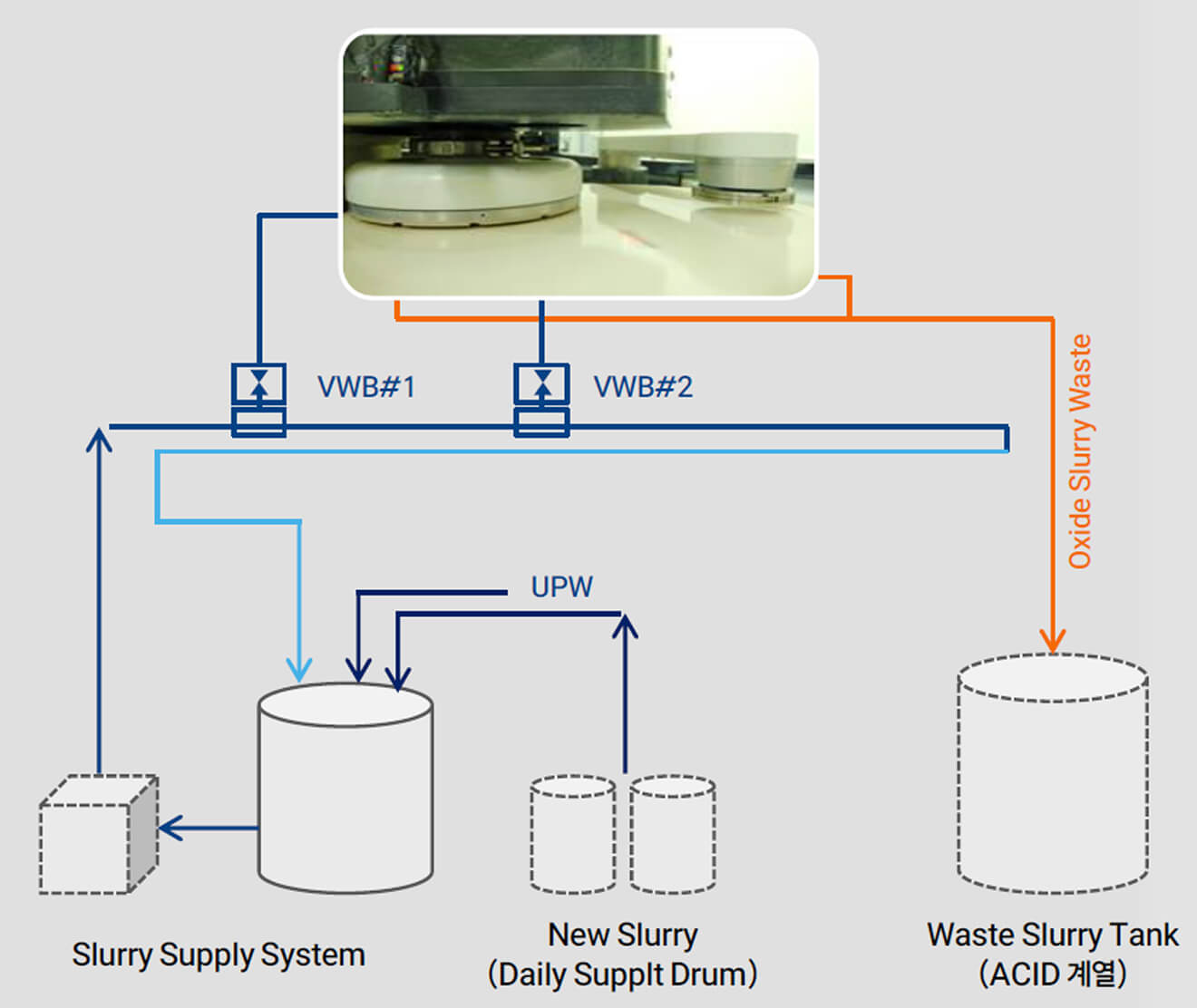

Polishing particles and chemicals can be recovered from impurities, and pure DI water can be extracted from that mixture, allowing for UPW recycling.

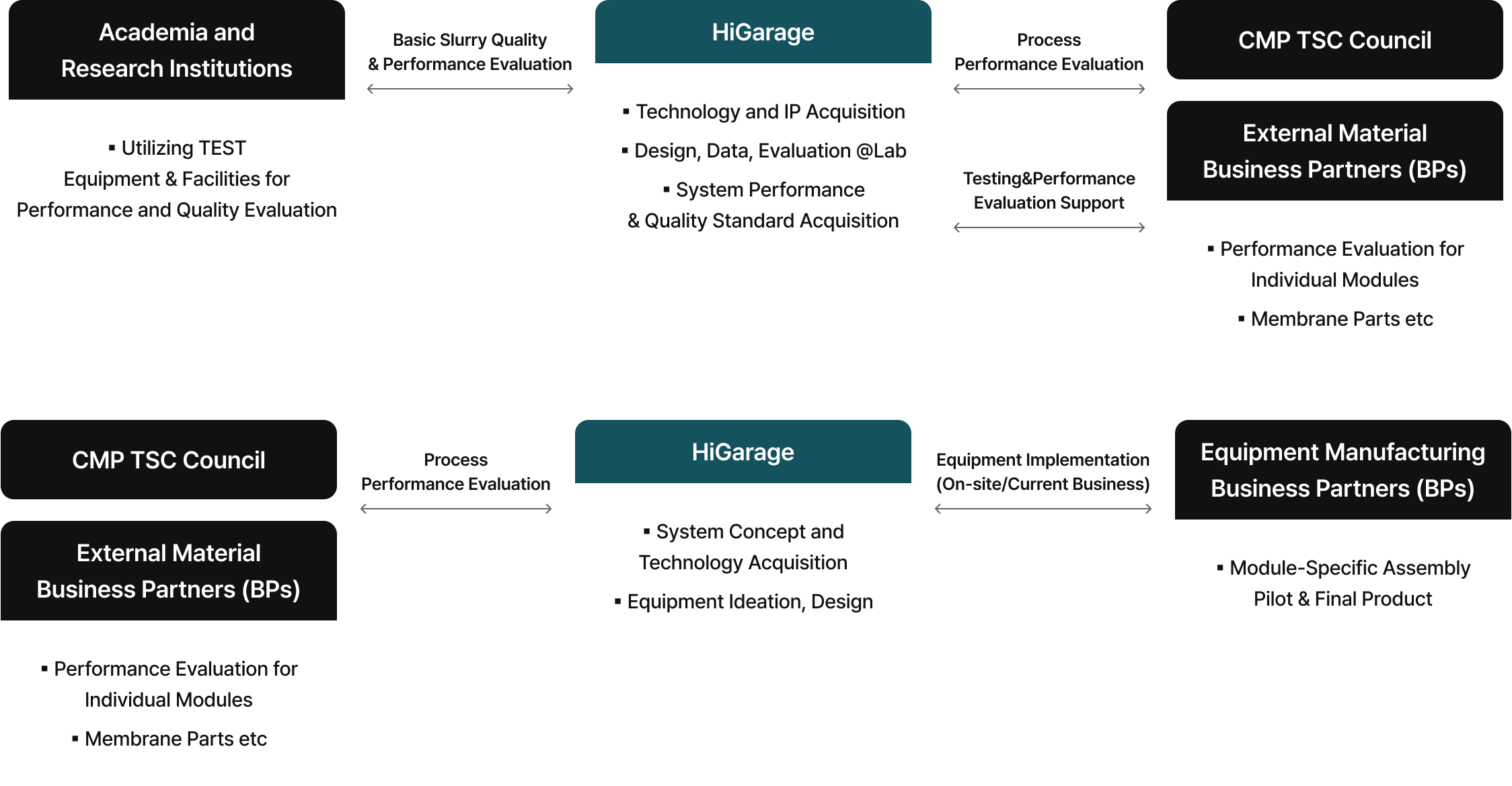

We secure slurry particle stability using Electric-Sonic technology and control the entire process in real-time with a Real-Time Monitoring system. We achieve uniform quality and high efficiency through precise control and immediate data feedback, completing a next-level smart process environment.

Slurries, which consist of an abrasive and DI Water for wafer planarization,

contain additives such as dispersants, oxidizers, pH adjusters, and corrosion inhibitors for particle stabilization,

depending on the type of semiconductor film being polished.

Copyright © 2025 neoresource. All Rights Reserved.

당사는 고객님의 정보를 중요시하며, 개인정보보호법을 준수하고 있습니다. 수집된 개인정보는 고객 여러분께 최적의 서비스를 제공하기 위한 목적으로 활용되며 최소한의 범위 내에서 개인정보를 수집하고 있습니다.

개인정보의 수집하는 목적 및 항목

수집목적 : ㅇㅇㅇ회사명 이벤트 제공 및 마케팅 활용

수집항목 : 성명, 연락처, 이메일주소, 주소 등

개인정보 수집방법 : ㅇㅇㅇ회사명 홈페이지 이용 등

개인정보의 처리 및 보유기간 / 보유기간 : 처리목적이 달성된 후 5년 이내 지체 없이 파기합니다.

개인정보 수집 및 이용 등의 철회 : 고객정보 및 이용을 원하지 않을 경우 철회요청을 할 수 있으며, 철회 시 이벤트 정보제공에 불이익을 받을 수 있음 / 개인정보 취급 및 위탁업무에 대한 안내

※ 부동의에 따른 고지사항 : 위 개인정보 수집 및 이용에 대해서 부동의할 수 있으나, 이 경우 홈페이지 이용에 제한이 있을 수 있습니다.